Description

Superior quality alloy rods

Alloy rod is a kind of high performance engineering material, which is widely used in machinery manufacturing, aerospace, energy and chemical industry. It is usually a mixture of a variety of metal or non-metallic elements, with excellent strength, corrosion resistance and special properties.The classification of alloy rod is diverse, according to the material can be divided into copper alloy rod, aluminum alloy rod, steel alloy rod, magnesium alloy rod and titanium alloy rod. These alloy rods have their own characteristics, such as copper alloy rods with good electrical and thermal conductivity, aluminum alloy rods are known for their light weight, high strength and corrosion resistance. In the production process, the alloy rod needs to undergo material preparation, melting, casting, heat treatment and other links. Through careful process control and subsequent treatment, alloy rods can achieve the required size, shape and performance requirements. Alloy rods are used in a wide range of applications, not only in the manufacture of various mechanical parts, molds and tools, but also play a key role in high-end fields such as aerospace, energy conversion and chemical production. Its high strength, corrosion resistance and special properties make alloy rods an indispensable material in modern industry.

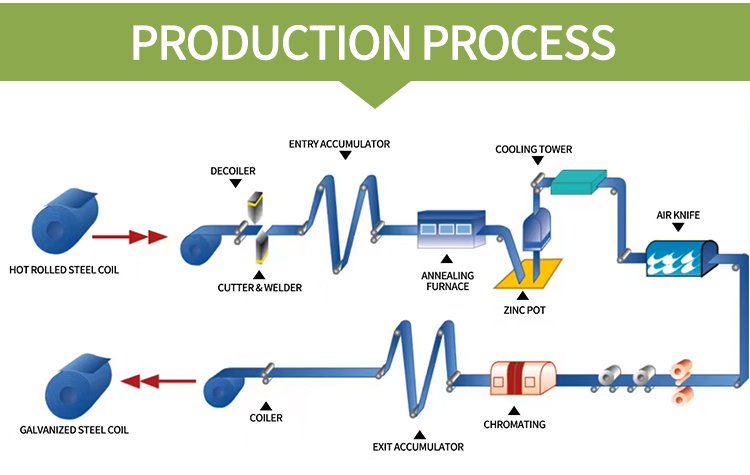

Professional production process

The production process of alloy rods is a comprehensive process, which mainly includes the following key steps:

Raw material preparation: According to the composition requirements of the alloy rod, the precise ratio and mixing of the required metal elements ensure the accuracy and uniformity of the alloy composition. Melting: The prepared raw materials are put into a high-temperature furnace and heated to above the melting point, so that the metal elements are melted and fully mixed to form a uniform alloy liquid. Heat treatment: Heat treatment of the alloy rod obtained by casting, including annealing, solution, quenching and other processes to improve the mechanical properties and structural stability of the alloy. Finishing: finishing the alloy rod after heat treatment, including turning, grinding, hole processing and other processes to obtain the final size and surface smoothness of the alloy rod. Quality inspection and packaging: At the end of each production process, the alloy rod quality inspection is carried out to ensure compliance with relevant standards and requirements.

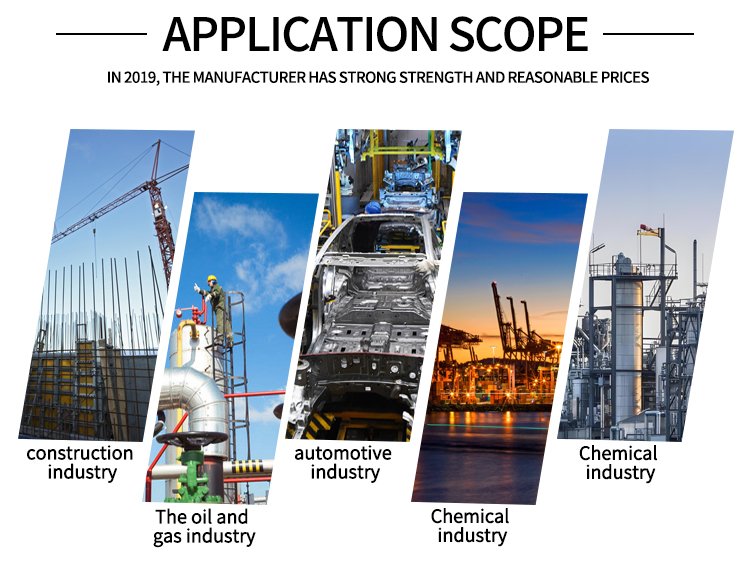

Product application scenario

The common use of alloy rod is very wide, in the field of mechanical manufacturing, alloy rod because of its high strength, high hardness and wear resistance, often used to manufacture mechanical parts, such as bearings, gears, threads and so on. These parts need to withstand high loads and friction, and alloy rods provide good wear resistance and mechanical properties. At the same time, alloy rods are also used to manufacture molds, such as plastic molds, die casting molds, etc., and their high precision and stability are crucial for mold manufacturing. In the aerospace field, alloy rods are particularly prominent in the aerospace field because of their lightweight, high strength and high temperature resistance. Alloy rods are widely used in the manufacture of airframes, engines, propellers and other components of aircraft, rockets, missiles and other aerospace devices.

Strong own strength

Liaocheng Zhentong Company takes pride in providing excellent customer service to customers all over the world. We focus on providing customized steel pipe solutions to meet the precise needs of our customers, and our commitment to service excellence ensures a smooth and satisfying experience. As a B2B wholesaler specializing in carbon steel pipes, we understand that our customers are buyers from large companies and steel buyers who need reliable and high quality products. Our products are exported to North America, India and Arabia and we strive to understand the specific needs and requirements of these markets. One of the main features of our products is the ability to customize according to customer requirements. We work closely with our customers to understand their specific needs and provide tailor-made solutions to meet their exact specifications. This ensures that our customers receive the best products for their applications. At Liaocheng Zhentong Company, we believe that excellent customer service is the key to building long-term relationships with our customers.

Service assurance

Liaocheng Zhentong Company believes that excellent customer service begins with a comprehensive understanding of customer needs. Our experienced team of professionals are always available to help and advise, from product selection to order processing and delivery. We ensure that our customers receive timely updates on the status of their orders and keep them informed of any changes or delays. We value effective communication and strive to ensure that our customers’ questions and concerns are addressed in a timely manner. Our customer service team can provide timely responses and solutions via email, phone and live chat. We also provide each client with a dedicated account manager to ensure their needs are met and their experience is the best it can be. We are committed to continuous improvement and to enhancing the customer service experience. Seek feedback from customers on a regular basis and use this information to identify areas for improvement. Whether it’s improving our product range, enhancing our delivery services, or providing additional support, we’re always looking for ways to exceed our customers’ expectations.

Related products

Related products

- +86 152 0654 8888

- aria@lczhentongsteel.com

- 1009, Building 2, Xingguang Financial Center, Liaocheng, Shandong, China

Services

Newsletter

Lorem ipsum dolor sit amet consec adipiscin elit ut elit el tellus, luctus nec ullamcorper.

Reviews

There are no reviews yet.