Carbon steel plate is a steel plate with carbon as the main alloying element, also known as carbon steel or carbon steel. Carbon steel plate has high strength and rigidity, and the cost is relatively low, so it has been widely used in manufacturing machinery, automobiles, construction and other fields. At the same time, due to its good electromagnetic properties, carbon steel plates are also widely used in the electrical and electronics industry.

In terms of manufacturing process, the manufacturing of carbon steel plate mainly includes the selection of appropriate raw materials, melting into molten steel, slag removal and impurity removal treatment, casting molding, heat treatment and subsequent cutting, bending, polishing and other processing operations. These steps together ensure the quality and performance of the carbon steel plate. In the processing of carbon steel, the commonly used forming processes include forging, pressure processing and sawing. These processes enable carbon steel to achieve the desired shape and size and improve its physical properties, wear and corrosion resistance.

In short, carbon steel plate is an important metal material, which has a wide range of applications in many fields. By understanding the material, performance, manufacturing process and processing method of carbon steel plate, we can better understand and apply this material.

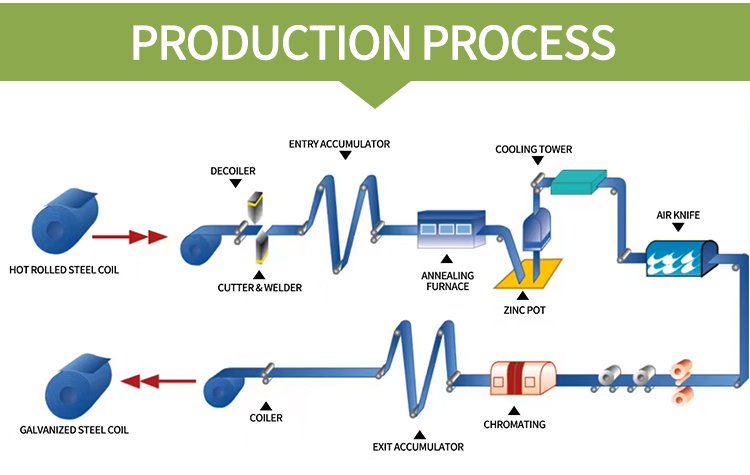

The production process of carbon steel plate can be briefly summarized as the following steps:

Raw material preparation: Select suitable raw materials, mainly including iron ore, scrap steel, etc. These raw materials are melted in blast furnaces in steel mills to form molten iron.

Casting: After high purity molten steel is processed, it needs to be cast into blank.

Hot rolling: The cast blank is hot rolled to produce the desired thickness and size of the steel sheet.

Pickling: In order to remove the oxide skin and rust on the surface of the steel plate and make the surface more smooth and smooth, pickling will be carried out.

Cutting: According to the actual needs and process requirements, the steel plate will go through the cutting process.

Heat treatment: Heat treatment is an important step to change the structure and performance of the steel plate, through heating and cooling, can improve the toughness, strength and wear resistance of the steel plate.

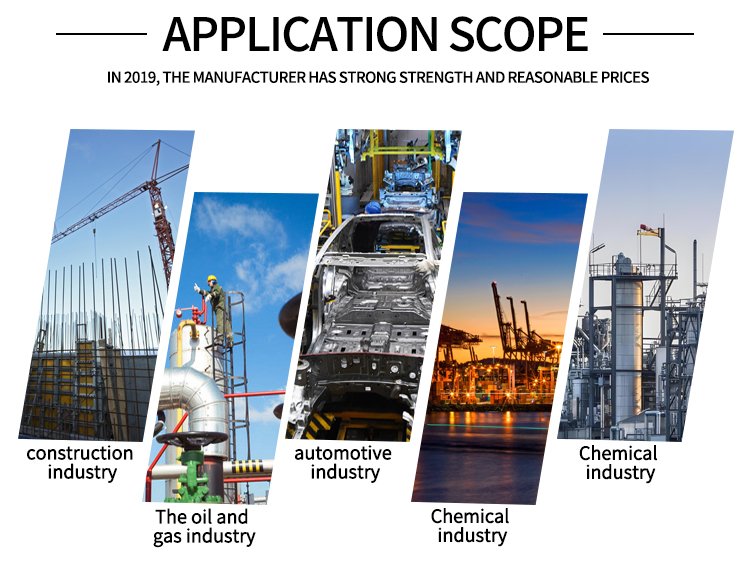

Carbon steel plate has a wide range of application scenarios, mainly because of its good mechanical properties, wear resistance, corrosion resistance and relatively low cost. The following are some of the main application scenarios of carbon steel plates:

Construction field: Carbon steel plate is often used in building structures, such as Bridges, house frames, support structures, etc. Its high strength and rigidity ensure the stability and durability of the building structure.

Mechanical manufacturing: In the field of mechanical manufacturing, carbon steel plate is the ideal material for manufacturing various mechanical parts, tools and equipment. For example, many parts of vehicles such as cars, ships, and aircraft are made of carbon steel plates.

Industrial equipment: Carbon steel plate also has a wide range of applications in industrial equipment, such as pressure vessels, storage tanks, pipelines, etc. Its good corrosion resistance and mechanical properties make it the material of choice for these devices.

Liaocheng Zhentong Company takes pride in providing excellent customer service to customers all over the world. We focus on providing customized steel pipe solutions to meet the precise needs of our customers, and our commitment to service excellence ensures a smooth and satisfying experience. As a B2B wholesaler specializing in carbon steel pipes, we understand that our customers are buyers from large companies and steel buyers who need reliable and high quality products. Our products are exported to North America, India and Arabia and we strive to understand the specific needs and requirements of these markets. One of the main features of our products is the ability to customize according to customer requirements. We work closely with our customers to understand their specific needs and provide tailor-made solutions to meet their exact specifications. This ensures that our customers receive the best products for their applications. At Liaocheng Zhentong Company, we believe that excellent customer service is the key to building long-term relationships with our customers. We strive to provide the best service and ensure that our customers receive the highest quality products and solutions. Contact us today to experience our commitment to service excellence.

Liaocheng Zhentong Company believes that excellent customer service begins with a comprehensive understanding of customer needs. Our experienced team of professionals are always available to help and advise, from product selection to order processing and delivery. We ensure that our customers receive timely updates on the status of their orders and keep them informed of any changes or delays. We value effective communication and strive to ensure that our customers’ questions and concerns are addressed in a timely manner. Our customer service team can provide timely responses and solutions via email, phone and live chat. We also provide each client with a dedicated account manager to ensure their needs are met and their experience is the best it can be. We are committed to continuous improvement and to enhancing the customer service experience. Seek feedback from customers on a regular basis and use this information to identify areas for improvement. Whether it’s improving our product range, enhancing our delivery services, or providing additional support, we’re always looking for ways to exceed our customers’ expectations.

Lorem ipsum dolor sit amet consec adipiscin elit ut elit el tellus, luctus nec ullamcorper.