Carbon steel pipe is made of ingot or solid round steel through perforation to make wool tube, and then through hot rolling, cold rolling or cold drawing process. This kind of steel pipe occupies an important position in China’s steel pipe industry and has a wide range of application fields. Carbon steel pipe is divided into hot rolled and cold rolled (drawn) two categories, including hot rolled carbon steel pipe including a variety of types, such as general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe; The cold-rolled (drawn) carbon steel pipe also includes carbon thin-wall steel pipe, alloy thin-wall steel pipe, stainless thin-wall steel pipe, shaped steel pipe and so on. These steel pipes are widely used in construction, machinery, oil drilling and mining and other fields, and their advantages are corrosion resistance, high strength and easy processing. In the preparation process, the raw material of carbon steel pipe is round tube blank, which is made through multiple processes such as cutting, heating, perforating, rolling, sizing, cooling, straightening, flaw detection, quality inspection and so on. In addition, the specifications of carbon steel pipes are expressed in millimeters of outer diameter and wall thickness, and their dimensional accuracy and performance can be adjusted according to specific needs.

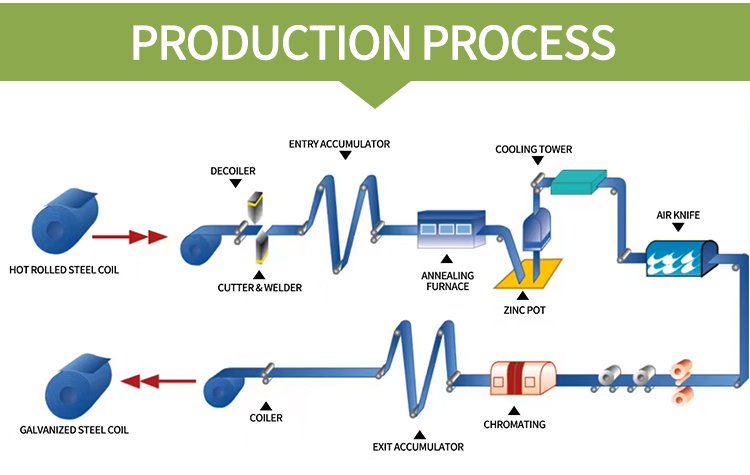

The production process of carbon steel pipes usually includes the following main steps:

Raw material preparation: First of all, the steel plate that meets the production needs needs to be prepared as a raw material. Steel plate cutting: Large steel plates are cut into billets of the desired size, which is carried out according to product requirements and design specifications.

Forming: The billet is bent by the machine to form the basic shape of the pipeline. Welding: For steel pipes that need to be welded, they are produced in the welding workshop.

Heat treatment: Heat treatment of welded pipes to improve their mechanical properties and corrosion resistance. Processing: The pipeline after heat treatment is processed to improve the appearance quality and dimensional accuracy of the pipeline.

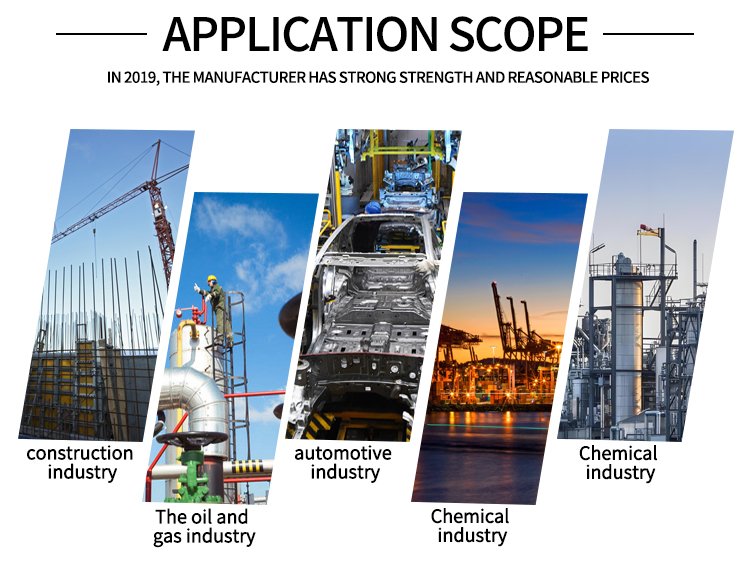

Carbon steel pipes have a wide range of application scenarios, mainly including but not limited to the following aspects:

Petroleum field: In the petroleum industry, carbon steel pipe is mainly used in oil well pipe, oil and gas transmission pipe, oil field casing and so on. Because the carbon steel pipe can resist corrosion and withstand high pressure, it can ensure the safety and stability of oil and gas transmission.

Chemical industry: In the chemical industry, carbon steel pipes are usually used to transport liquids or gases.

Aviation: The application of carbon steel pipes in the aviation field is mainly to manufacture various pipes and supports on aircraft. Because of its light weight, high strength, good ductility and other characteristics, it can meet the requirements of high strength and lightweight materials for aircraft structures.

Construction field: In the construction field, carbon steel pipes are mainly used as support and transportation systems for building structures, such as stair handrails, ground paving, electrical lines, hot water supply pipelines, water supply pipelines, gas transmission, etc.

Liaocheng Zhentong Company takes pride in providing excellent customer service to customers all over the world. We focus on providing customized steel pipe solutions to meet the precise needs of our customers, and our commitment to service excellence ensures a smooth and satisfying experience. As a B2B wholesaler specializing in carbon steel pipes, we understand that our customers are buyers from large companies and steel buyers who need reliable and high quality products. Our products are exported to North America, India and Arabia and we strive to understand the specific needs and requirements of these markets. One of the main features of our products is the ability to customize according to customer requirements. We work closely with our customers to understand their specific needs and provide tailor-made solutions to meet their exact specifications. This ensures that our customers receive the best products for their applications. At Liaocheng Zhentong Company, we believe that excellent customer service is the key to building long-term relationships with our customers. We strive to provide the best service and ensure that our customers receive the highest quality products and solutions. Contact us today to experience our commitment to service excellence.

Liaocheng Zhentong Company believes that excellent customer service begins with a comprehensive understanding of customer needs. Our experienced team of professionals are always available to help and advise, from product selection to order processing and delivery. We ensure that our customers receive timely updates on the status of their orders and keep them informed of any changes or delays. We value effective communication and strive to ensure that our customers’ questions and concerns are addressed in a timely manner. Our customer service team can provide timely responses and solutions via email, phone and live chat. We also provide each client with a dedicated account manager to ensure their needs are met and their experience is the best it can be. We are committed to continuous improvement and to enhancing the customer service experience. Seek feedback from customers on a regular basis and use this information to identify areas for improvement. Whether it’s improving our product range, enhancing our delivery services, or providing additional support, we’re always looking for ways to exceed our customers’ expectations.

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!

Lorem ipsum dolor sit amet consec adipiscin elit ut elit el tellus, luctus nec ullamcorper.